Unvented Roof Assemblies for all Climates

This article was taken from the Building Science Corporation site: www.buildingscience.com, and Building Science Corporation, retains copyright to it. Check out the full article here: Building Science Corporation

Abstract:

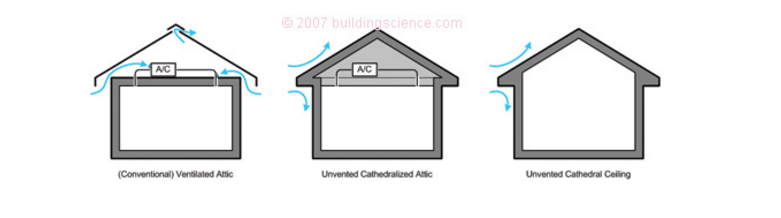

Unvented roof assemblies, such as conditioned attics and unvented cathedral ceilings, are becoming common in North American construction. These assemblies are created by eliminating ventilation openings and moving the thermal, moisture and air control boundaries to the plane of the roof deck. This document provides a brief description of different types of unvented roof assemblies and the benefits of unvented roof construction.

Unvented roof assemblies, such as conditioned attics and unvented cathedral ceilings, are becoming common in North American construction. It is estimated that over 100,000 have been constructed since 1995. These assemblies are created by eliminating ventilation openings and moving the thermal, moisture and air control boundaries to the plane of the roof deck.

Why Unvented Roof Assemblies?

Unvented roof assemblies address a number of issues that are important to homeowners, designers, builders and society:

Health & Comfort – In many houses air leakage between the living space and the attic is not properly controlled. Air-conditioning equipment, exhaust fans, ductwork, attic access hatches, recessed lighting and even plumbing & electrical penetrations create holes that connect the living space to the attic.

Pressures created by the mechanical equipment, as well as wind and temperature differences, cause air to move between these spaces leading to great energy waste and occupant discomfort.

This uncontrolled movement of air can also carry moisture to cold surfaces where it can condense. In hot humid climates outdoor air can condense on the air-conditioning equipment and ductwork typically located in attic spaces; in cold climates warm indoor air leaking into the attic can condense against the underside of the roofsheathing.

Contaminants (including volatile organic compounds or VOCs) resulting from premature building material degradation due to the uncontrolled movement of moisture laden air can migrate from the attic into the living space.

In unvented roof assemblies the thermal, moisture and air control boundaries are moved to the roof deck so that the attic space is at the same condition as the living space and air movement between the two does not contribute to energy waste, occupant discomfort or contaminant problems.

Energy– When air-conditioning equipment and ductwork are located in conventional ventilated attics, they must be insulated and air sealed. This is often difficult to accomplish. Even when air sealing is done well, there remain large energy-wasting temperature differences (up to 150°F or 65°C) between the air in the ductwork and the air in the attic for hundreds to thousands of hours a year. It is not practical to sufficiently insulate the ductwork and equipment against this.

If the thermal, moisture and air control boundaries are moved to the roof deck to create an unvented conditioned roof assembly, the load on the mechanical equipment is significantly reduced and ductwork leakage will occur to or from the conditioned living space.

Durability – Openings in the soffits, gables, mushroom and ridge vents allow more than just air to enter the attic. In cold northern climates snow can be blown in through these openings, accumulating, melting and causing damage to the ceiling or creating the potential premature structural failure or mold growth inside the roof assembly. In coastal climates wind driven rain can be blown in through these openings with similar results. In areas subject to wildfires, burning embers can be blown in through these openings, potentially starting roof fires.

Unvented roof assemblies are not prone to these problems because the ventilation openings have been eliminated.

Value – Many homeowners see value in finished attics that can provide more living space and conditioned storage space. Additionally, designers are using increasingly complicated roof geometries and providing spaces with high cathedral ceilings. These create problems for conventional ventilated roof assemblies because the geometry makes it impossible to ensure airtightness at the ceiling plane. Furthermore, ventilation spaces become small and complex, making it difficult to ensure adequate flow rates or distribution of ventilation air inside the ventilated assemblies.

The ventilation space can be eliminated and the construction greatly simplified by using an unvented roof assembly.

Why Use Closed-Cell Spray Polyurethane Foam (ccSPF)?

Closed-cell spray polyurethane foam can be used to create an unvented roof assembly that works in all climatezones. The design approach is the same for all climate zones.

Ymker Insulation

Ymker Insulation